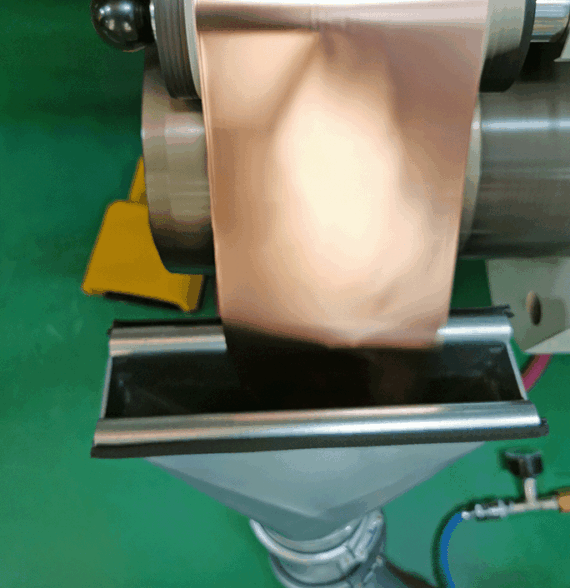

Manufacturers of lithium-ion (Li-ion) batteries face unique challenges during the slitting and rewinding of copper and aluminium foil. Thin, delicate materials generate continuous edge trim waste that must be handled cleanly and efficiently to maintain high production speeds and product quality.

At Lundberg Tech we specialise in providing advanced trim removal systems designed to integrate seamlessly into your slitting and rewinding lines — ensuring maximum uptime, clean working environments, and precise waste handling for copper and aluminium foil.

Our next event: Converters Expo 2026

In Li-ion battery manufacturing, copper and aluminium foils serve as critical components for anode and cathode materials. During slitting, long edge trims are generated and must be removed efficiently, without contaminating the process, or causing machine downtime.

Without an effective trim removal system, foil processors risk:

- Foil build-up causing machine stoppages

- Irregular trim tension leading to wrinkling or web breaks

- Time-consuming manual waste collection

Lundberg Tech’s trim removal solutions are built to eliminate these risks through smart, automated systems that are reliable, safe, and low maintenance.

Benefits & features There are many benefits using an automated waste handling system, to name a few:

- Continuous, automated trim extraction: Our systems continuously extract trims from high-speed slitting and rewinding lines, reducing manual handling and keeping machines running longer

- Dust and particle control: Ideal for copper and aluminium foil, our solutions can include automatic filters and collection bins to enhance workplace safety and cleanliness

- Customised for your foil slitting process: We design our trim removal units to accommodate the specific slitting process at your facility

- Centralised waste management: Trim can be conveyed to a compactor or collection point — streamlining recycling and keeping production areas clean.

- Increased uptime, reduced maintenance

By eliminating manual trim handling and foil build-up, our systems significantly reduce downtime and improve operational efficiency, allowing you to scale battery production confidently.

Tailored solutions for battery foil producers

We understand that no two slitting lines are alike. Lundberg Tech works closely with you to engineer the ideal trim removal solution for your specific production layout, foil specifications, and capacity targets. Whether you run multiple foil widths, different materials or need redundant systems, we deliver.

Lundberg Tech is a trusted name in waste handling and trim removal technology, with decades of experience supporting industrial converters and manufacturers worldwide. Our systems are already in use in leading Li-ion battery production plants, helping them achieve consistent output, better material recovery, and improved safety standards.

Learn more about our waste handling solutions