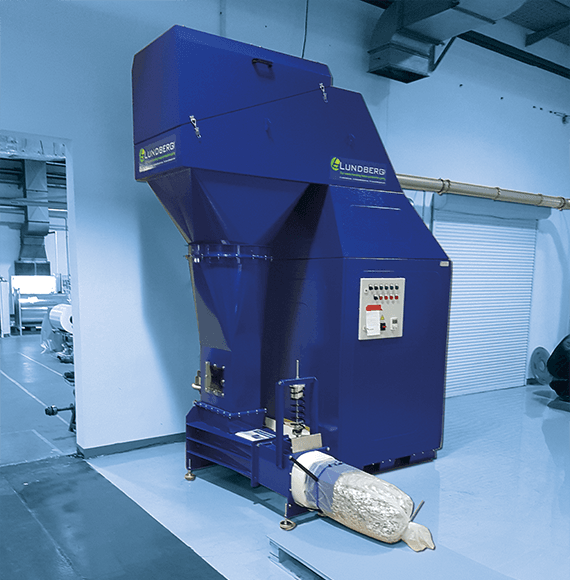

TrimCompactor – the obvious choice

In an excellent way the Lundberg Tech TrimCompactor Unit combines the ability to capture, convey, cut, collect and compact waste from a wide range of production and packaging machines generating waste like edge trim, skeleton, matrix and die cuts.

The TrimCompactor is the obvious All-in-one Unit choice when it comes to supporting sustainability and circular economy in your production or packaging process.

The TrimCompactor can handle waste from one or more machines. Upon demand it can be equipped with one or more of the Lundberg Tech own designed and manufactured Granulators.

Benefits & features Benefits and advantages using the TrimCompactor:

- Reduces the volume of waste

- Removes the dust along with the waste

- Frequency converter for adjusting the suction power

- Makes waste handling easy for your staff

- Easy installation

- Supporting continuous operation

- Compacting the waste in a TubeBag easy to remove

The TrimCompactor All-in-one Unit is a complete unit equipped with ventilator, sound silencers, waste separator, air filter and compactor. By combining all these necessities for an effective waste handling the unit do have a limited footprint and can be located up to 20m from the machine(s) the unit is serving.

The TrimCompactor All-in-one Unit is available in five different sizes:

- TrimCompactor 80 – 1 process machine

- TrimCompactor 140 – up to 4 process machines

- TrimCompactor 200 – up to 8 process machines

- TrimCompactor 400 – up to 16 process machines

- TrimCompactor 600 – up to 24 process machines

The TrimCompactor can be delivered with more options like:

- Antistatic bars for removal of static electricity from the material processed

- Other types of filter systems, including automatic self-cleaning filter

- More Granulators with all Granulators outside the cabinet

- Table to support the unit for delivering the compacted waste into a wheel bin

The TrimCompactor is a very special unit which can also help you prepare your waste for recycling and deliver the compacted waste in a “sausage” in the length you desire.