Reducing environmental impact is a primary concern for every business. This goes beyond moral obligations to protect our planet for tomorrow, it is a vital part of any future-focused growth strategy to maintain competitiveness and compliance.

When it comes to waste reduction, the focus tends to be on what happens to packaging after the consumer is finished with it. However, a great deal of waste can be dealt with effectively if handled in a smarter way during the production and packaging phase.

This is particularly relevant for slitting, converting, and packaging – processes that inevitably create waste. Here, implementing an automated waste handling solution is one of the best ways to run a more sustainable operation and lower your environmental footprint.

The problems with manually handling waste

Often in slitting, converting, and packaging, waste handling is still being done either fully or semi manually. While this may be a feasible option for startups or smaller operations, as soon as production ramps up, automating the process is a far better option.

Putting productivity bottlenecks and worker safety issues aside for now (see our other blogs for more on these issues), a fully or semi manual waste handling process simply cannot deal with waste efficiently or effectively, which can have serious repercussions from an environmental perspective.

Firstly, the size and shape of the waste results in a large volume of material that is inefficient to transport. Secondly, it is virtually impossible segregate waste material into individual types, which leads to issues when it comes to recycling for the same product or for a composite material.

Automation helps efficiency, recyclability, and composting

This is one area where an automated waste handling solution can make all the difference.

A key feature of these systems is its Granulator. This is a specially designed piece of equipment that cuts up waste into small pieces before it is conveyed elsewhere. And smaller pieces of waste are much easier to deal with in several ways.

The first of these involves its volume. The smaller your waste becomes, the less space it takes up. This makes it far more efficient to transport, either within your own facilities or, more importantly, when it goes back to the original supplier for recycling or compositing. The fewer trips this involves, the less fuel is consumed and the less CO2 is emitted, along with all the other hidden factors that play a role in its environmental impact, such as noise pollution, road congestion, component wear and tear, etc.

As well as this, automated waste handling systems also excel at sorting and segregating waste. This, much like cutting, could not be done by hand, ensuring that paper, cardboard, plastics, or other materials from your process find their way into correct recycling and composting streams. This can significantly reduce the amount of real waste, thereby promoting a more circular economy.

Proper material segregation also helps the waste material to be integrated into a composite, which is where it finds a new life in an entirely different application, such as for roads or insulation. Automated waste handling systems can sort materials based on predefined criteria, such as type and color, which minimizes the cross-contamination that can affect the quality of the new product it becomes.

Use less energy

Another benefit of automated waste handling systems is that they can also help you to save energy in your production process.

By continuously removing waste from your production or packaging machine, your operators do not need to constantly stop and start them to deal with the waste by hand. If you are running multiple machines in multiple sites, these savings can add up significantly over time, especially if you also factor in the loss to your productivity that would otherwise also occur.

Compared to a Venturi system that simply blows waste trims and dust to one side, fully automated waste handling systems also require less energy to run. Furthermore, they keep the dust inside the system, thereby helping to keep the surrounding environment clean.

Stay on the right side of regulations

Another important factor to note is that businesses today face stringent environmental directives, such as the EU’s Environmental Development Goals and demands for ESG reporting that guide and govern waste management practices. Many of these are compulsory and businesses are required to be more transparent regarding their environmental efforts and initiatives than ever before.

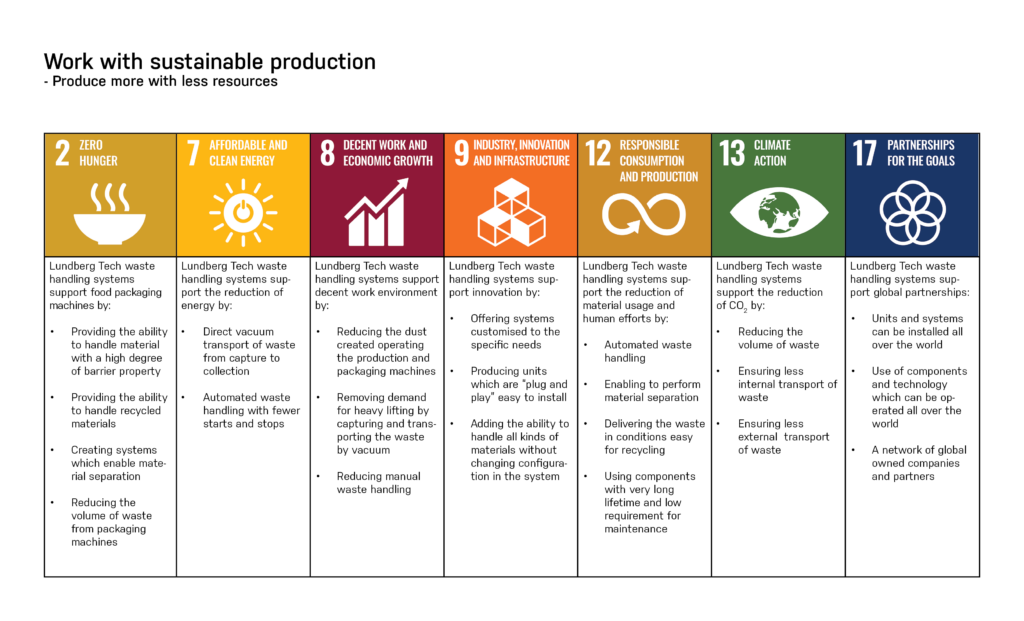

Lundberg Tech’s automated waste handling solutions are specifically designed to address these issues, helping you to create a more sustainable production and packaging process. This is outlined in the following table:

With automation, everybody wins

An automated waste handling system is one of the best ways to help you achieve your sustainability goals and position you as a forward-thinking, responsible business. In slitting, converting, and packaging, it’s a win-win-win scenario: environmental stewardship, standards compliance, and greater production efficiency.

By embracing these systems, you can contribute to a more sustainable, circular industry while optimizing your competitiveness at the same time. Contact us today to learn more about the difference it could make to your operations, and to the planet.

If you are interested in the latest news. Sign up to our newsletter and stay informed!