The ideal waste handling solution for your label processes

The Lundberg Tech MatrixCompactor is our All-in-one solution for the label industry. The MatrixCompactor is available in four different sizes and can capture self-adhesive matrix and trims from one to six label presses with one unit.

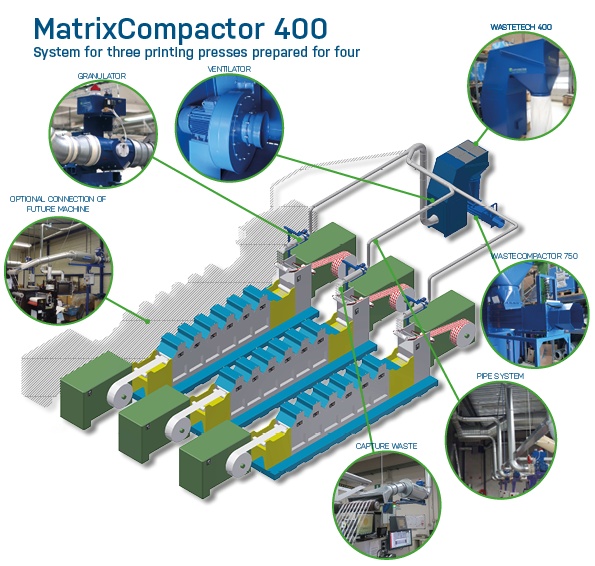

The MatrixCompactor is a complete waste capturing system. The system includes Granulators for each label press, a pipe system for conveying the waste, transport ventilator, air/waste separator, air filter and a WasteCompactor ensuring that the adhesive waste is compacted. The inside of the MatrixCompactor and the pipes for the system are all treated to ensure that the adhesive material does not stick on the surfaces. At the same time the Granulator is equipped with our oil dispensing system to prevent residue build-up on the knives.

Benefits & features Using a MatrixCompactor for collecting label and tag waste gives several benefits:

- Increase throughput – no need to stop to remove matrix rolls

- Improve workplace environment – fewer heavy lifts and less waste bins in the production area

- Reduce material usage – fewer stops mean less material wasted when starting the press

- Cut waste into small pieces – reduces the volume of the waste

- Collect and compact waste centrally – compacted waste is more dense than rolls with matrix

The MatrixCompactor also works with other Units

The MatrixCompactor can also work in tandem with one of our other All-in-one Units. As an example, you can collect the adhesive matrix label waste in the MatrixCompactor, and your glassine release liner trims can be collected in a WasteTech. In this way the material is separated and the glassine can be recycled separately.

The MatrixCompactor is equipped with our WasteCompactor that compacts the waste into a “sausage style” bag, alternatively the waste can be compacted directly into a roller bin. In both cases the volume of the adhesive waste is reduced drastically compared to a roll of matrix waste.

The MatrixCompactors are available in four different sizes:

- MatrixCompactor 140 – for one label press

- MatrixCompactor 200 – for two label presses

- MatrixCompactor 400 – for up to four label presses

- MatrixCompactor 600 – for up to six label presses

For the MatrixCompactor series several options are also available, such as:

- Antistatic bars, for static loaded plastic materials

- Cartridge filters, for longer intervals between filter cleaning

- Automatic self-cleaning filter systems

- Touchscreen display with data collection