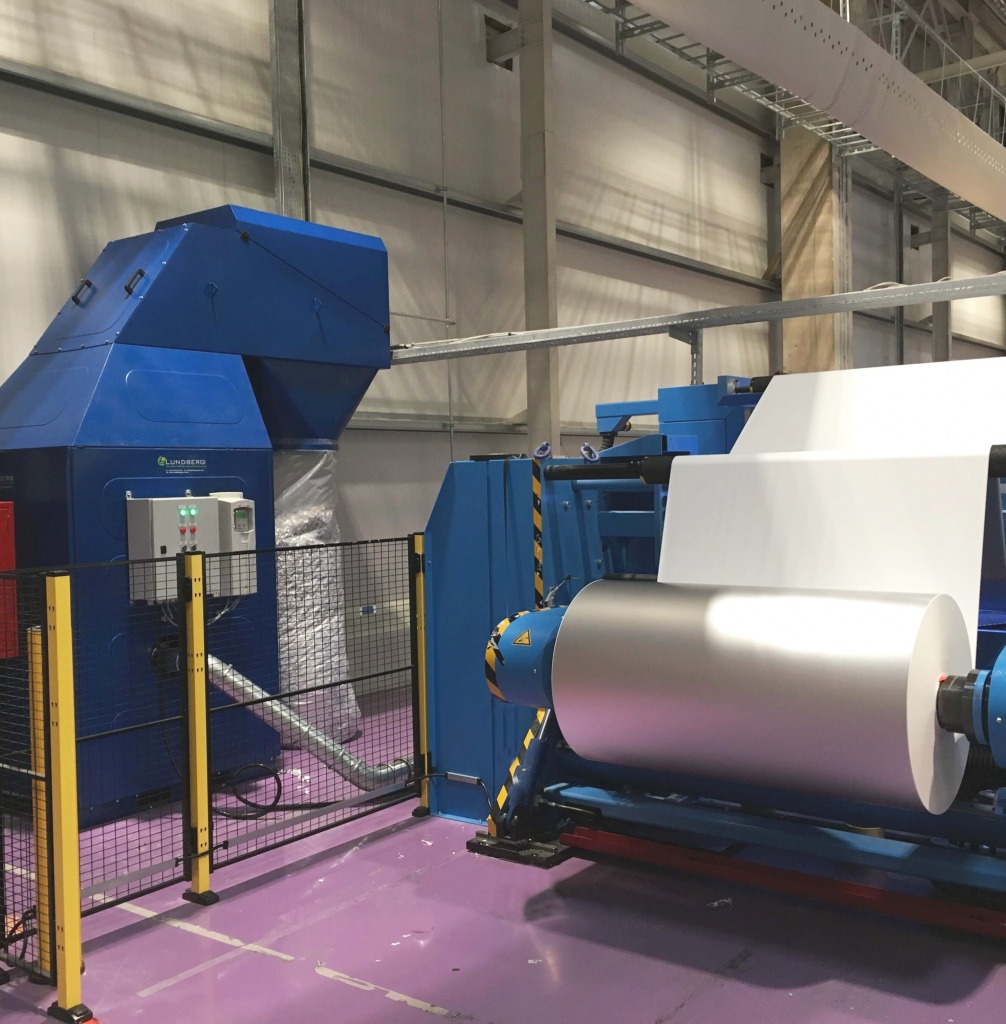

Well-known All-in-one vacuum waste handling units

The Lundberg Tech WasteTech All-in-one Units range provides efficient waste handling for a wide range of applications, including printing, packing and other production machines

The range of WasteTech All-in-one Units has an air capacity range from 900 to 10000 m2 per hour, which means that we can handle anywhere from a single machine up to 20 production machines. The WasteTech series can capture, cut, convey and collect many types of process waste including trims, matrix and die cuts.

Benefits & features Benefits and advantages of the WasteTech All-in-one Units

- Reduce the volume of waste

- Remove the dust along with the waste

- Make waste handling easy for your staff due to no manual handling of waste

- Easy installation

- Available with guillotine valve for continuous operation

- Can be customised to specific type of waste materials and shapes

- Easy access to critical parts

All WasteTech Units can be delivered with numerous options:

- Endless bags – TubeBag for continuous operation

- Height extension for more volume in the bag

- Level sensor for full bag

- Antistatic bars for removal of static electricity from the material processed

- Non-stick inside coating and oil system for handling adhesive materials

- Oil system for handling adhesive materials

- Frequency converter for adjusting suction power

- Other types of filter systems, including automatic self-cleaning filter

- Compactor for compacting the waste – e.g. our WasteCompactor

- More Granulators with all Granulators outside the cabinet

Lundberg Tech also installs waste handling systems around the world in which the All-in-one Units form the collection unit for the materials that should be recycled. This is often done in combination with a Central System handling the material where recycling is not currently possible.